The Future of Direct Liquid Cooling is Much More Complex

Integrated direct liquid cooling and 3D printed directed flow cooling

At this week’s Intel Foundry event, the company showed off capabilities around different types of thermal interface materials (TIM), thermal profiling and solution design, and more. One of the more interesting pieces was around how the company can design liquid cooling with the package. Several places picked this up, including STH. What was shown at the event was really a start. For tomorrow’s big AI packages, a different solution will be required, and we were able to grab some photos of what those solutions look like.

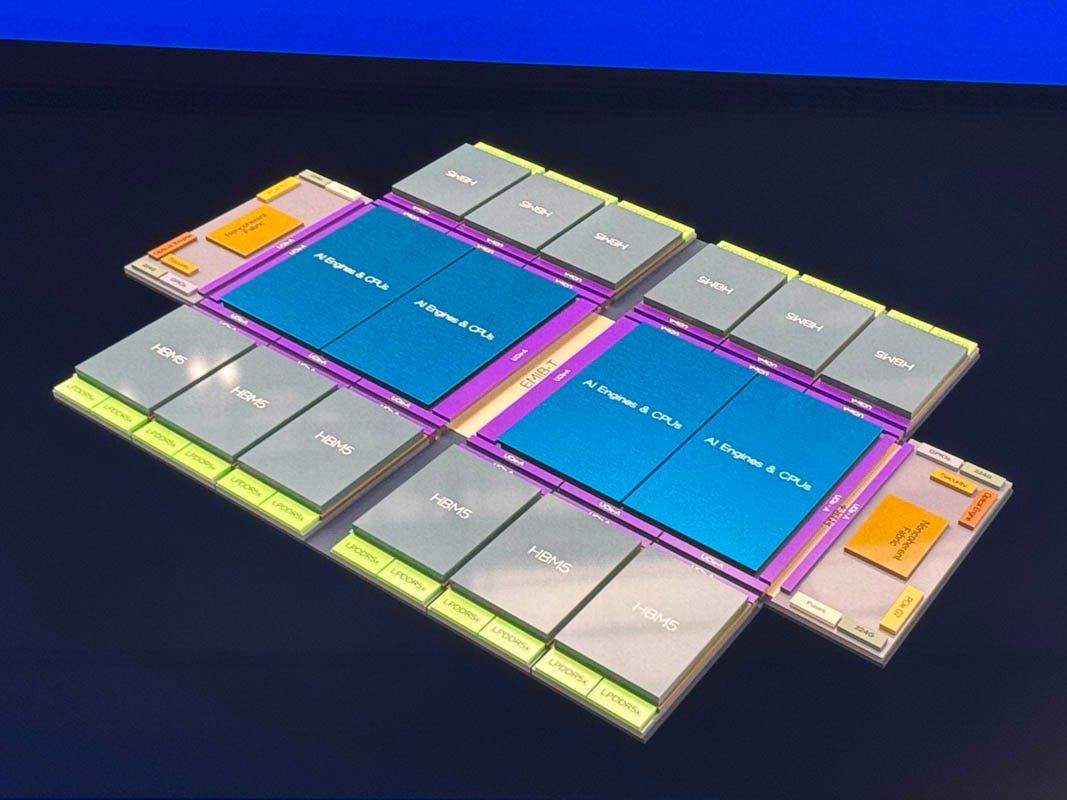

One of the key drivers of this is a package that looks similar to this one:

Today’s Needs Are Relatively Simple, as Are Solutions

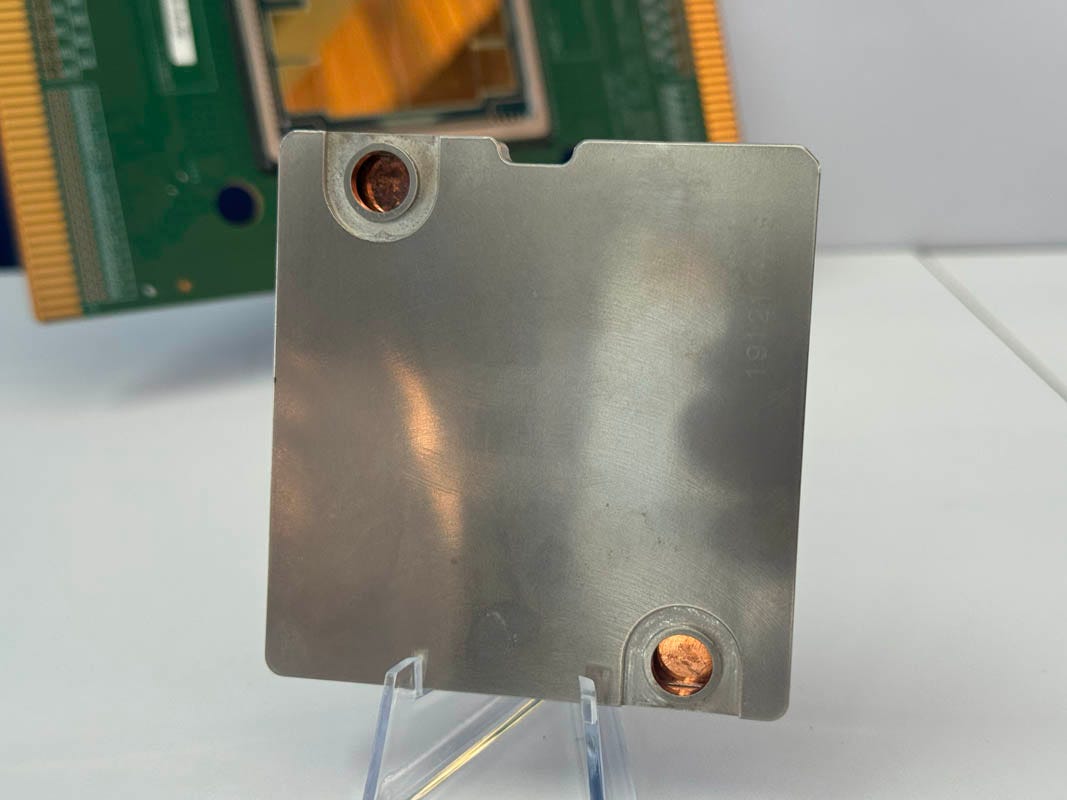

At the event, Intel displayed a number of cold plates that are essentially liquid cooling plates that could be designed alongside chips to help manage the heat that the packages generate.

You can see on the slide that these integrated cold plates use standard vertical fins to manage fluid flow through the cold plates.

If you look at the packages shown, they have these simple vertical fins. Often the fins are made of copper and fluid flow goes through the fins in a manner analogous to how air flows through a large air cooling heatsink.

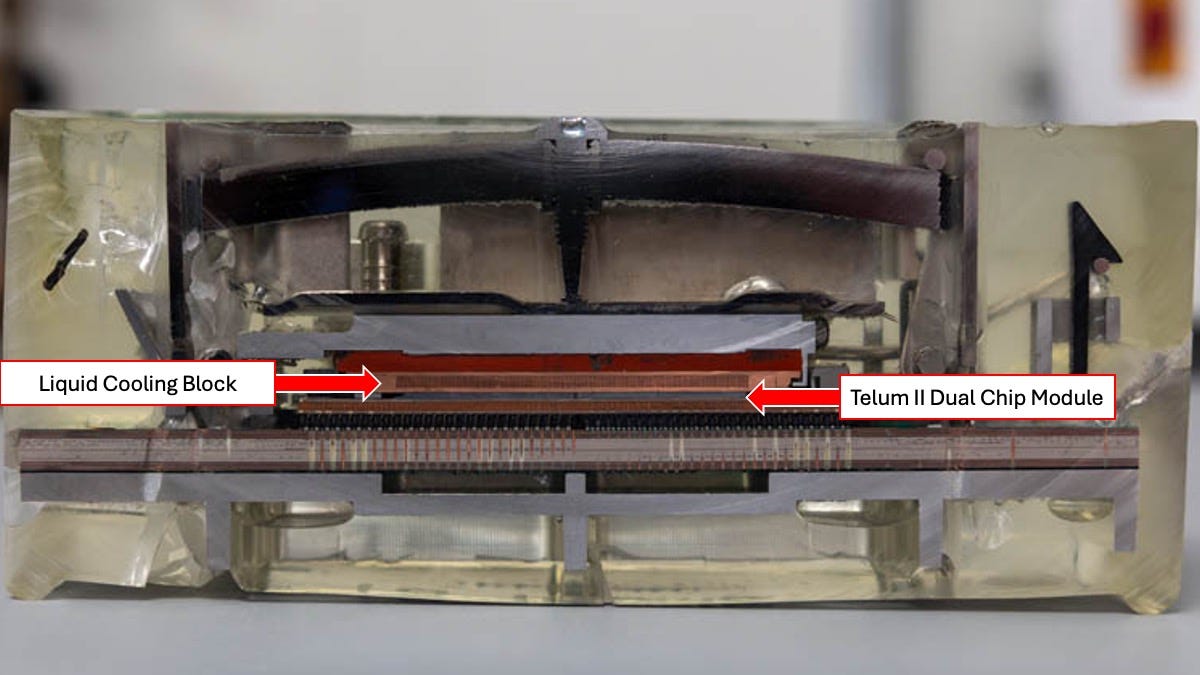

Even the new IBM z17 mainframe’s Telum II processors are cooled using a design like this, as shown in the cutaway view.

IBM’s socket design uses several pistons to manage pressure across the socket and then a thin sheet of TIM between the cooler and the Telum II dual chip module or DCM.

Even today’s large GPUs utilize chip-to-TIM to liquid cooling blocks in their designs. What we saw at the event, however, was something very cool indeed. It also sounded like Intel is looking into the technology, which makes a lot of sense for next-generation chips. Let us dig into that next.